Architectural Clay Formworks was a 2020-21 independent study by Jacob Gasper and Cyle King with advisor Shelby Doyle, AIA. The full research portfolio can be found here.

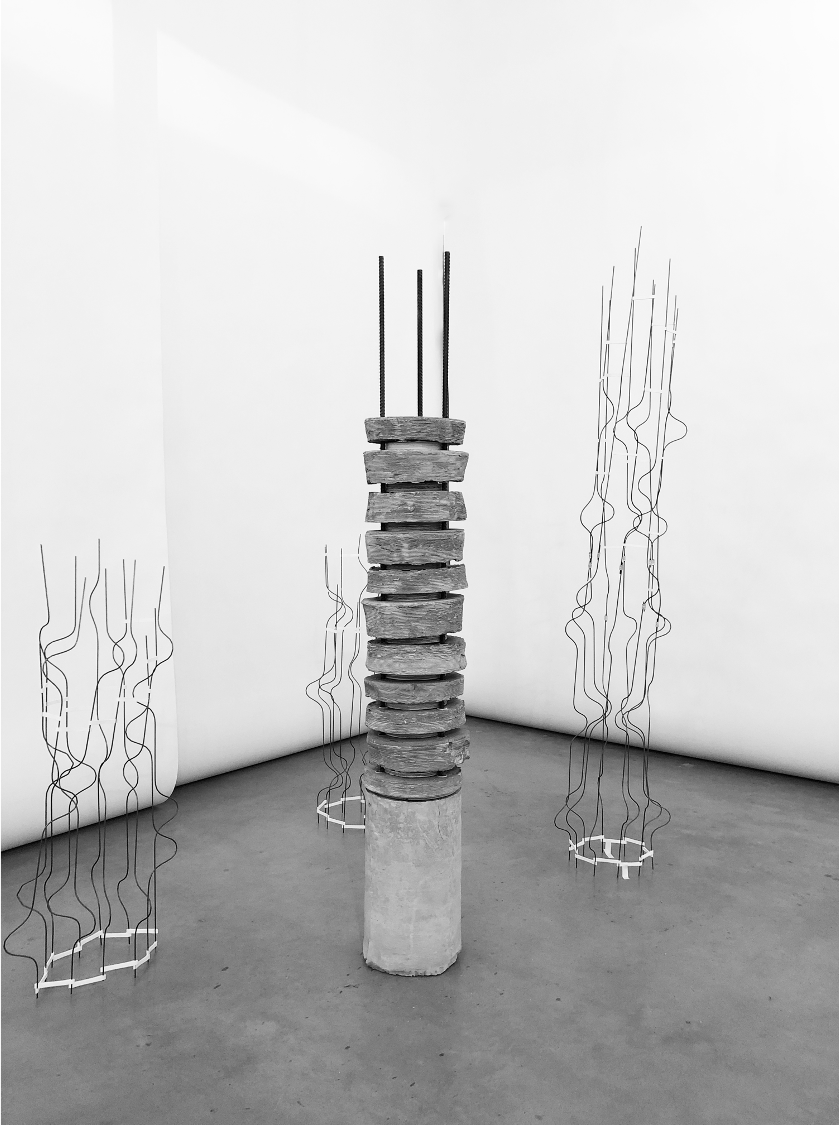

This body of work explores 3d printing clay as a reusable formwork for concrete applications. This project began with a literature review and case studies to scope a research agenda and expand upon the possibility of 3D printing clay for the design and production of reusable concrete formwork. This research developed methods and mock-ups for unfired clay 3D printing, both for its geometric possibilities and limitations as a reusable architectural formwork. The hypothesis of this project was that clay can be 3D printed to produce a mold, poured into to produce a concrete cast, then dissolved, remixed, and then used to produce new prints and molds. The project methodology relied upon iterative digital fabrication to combine robotic fabrication knowledge, computational design, and ceramic knowledge. Resulting work is evaluated for replicability and aesthetics. The outcomes were mock-ups of architectural elements that reduce formwork material use and demonstrate the viability of the proposed methods.

Beginning in 2019 as a series of seminars and independent studies this work began with the design and development of a pressurized air extrusion system that works with a KUKA industrial robotic arm located in the ISU Student Innovation Center Architectural Robotics Lab. Initial iterative studies focused on clay consistency, end effector design, compressed air calculations for pressuring clay, and robotic arm travel velocity to produce clay prints.

Funded in part by the Iowa State University Foundation. Funded in part by the Iowa State Honors College. Supported by the ISU Computation + Construction Lab