The following is basic documentation of the hardware and software necessary to adapt an ‘off-the-shelf’ LulzBot Taz HS+ 1.2 Tool Head for use on a KUKA KR-1100 Industrial robotic arm with a heated bed.

This work is a part of an ongoing collaboration between Shelby Doyle, Nick Senske, and Erin Hunt and was supported by grants from ARCC, AIA Upjohn, and Autodesk.

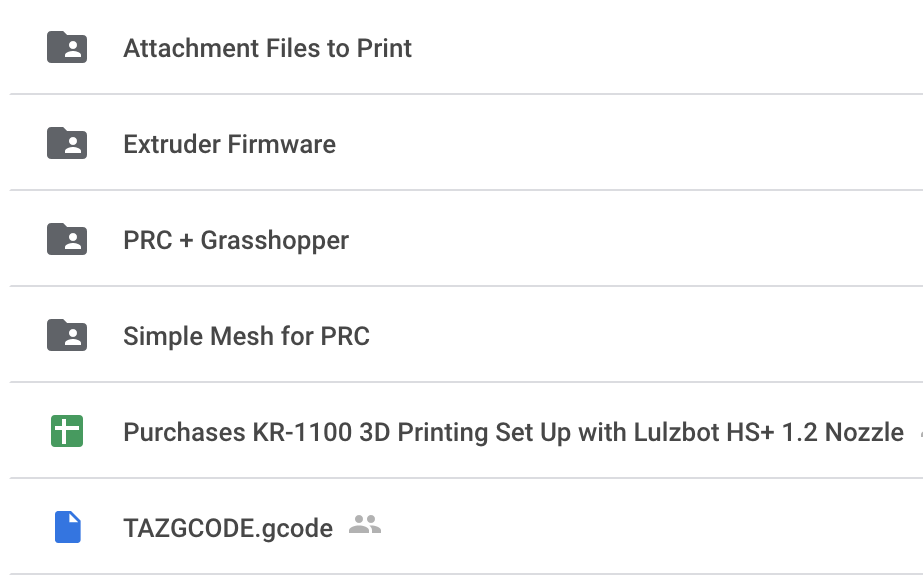

The image below links to a Google Drive Folder with following supporting files.

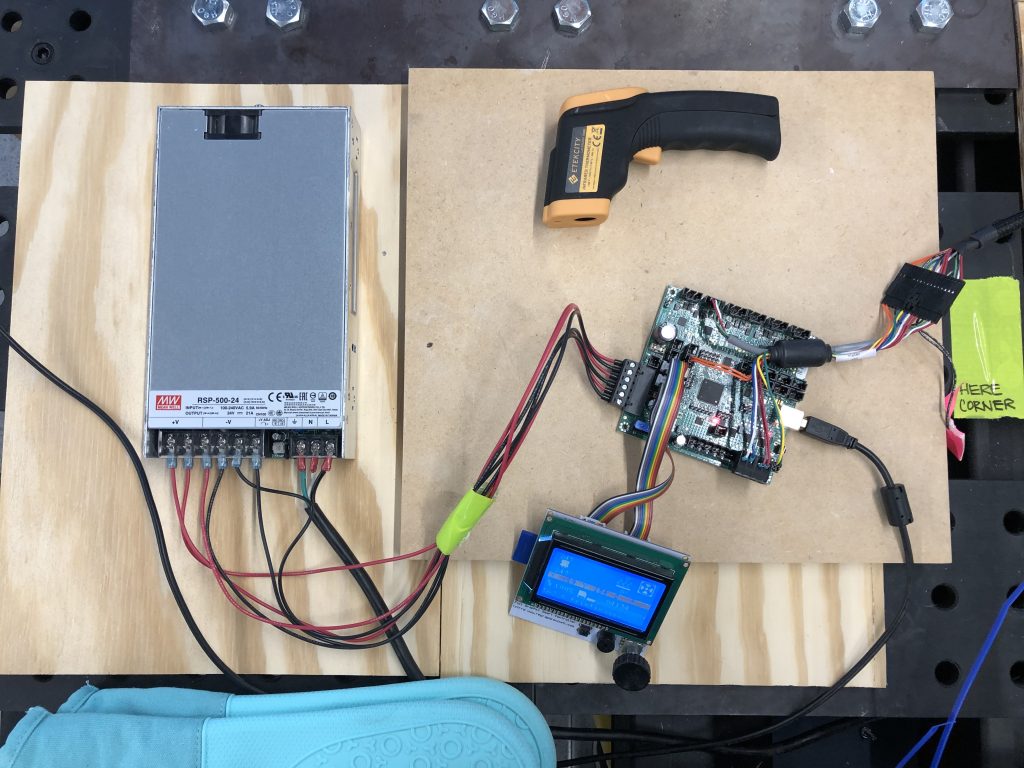

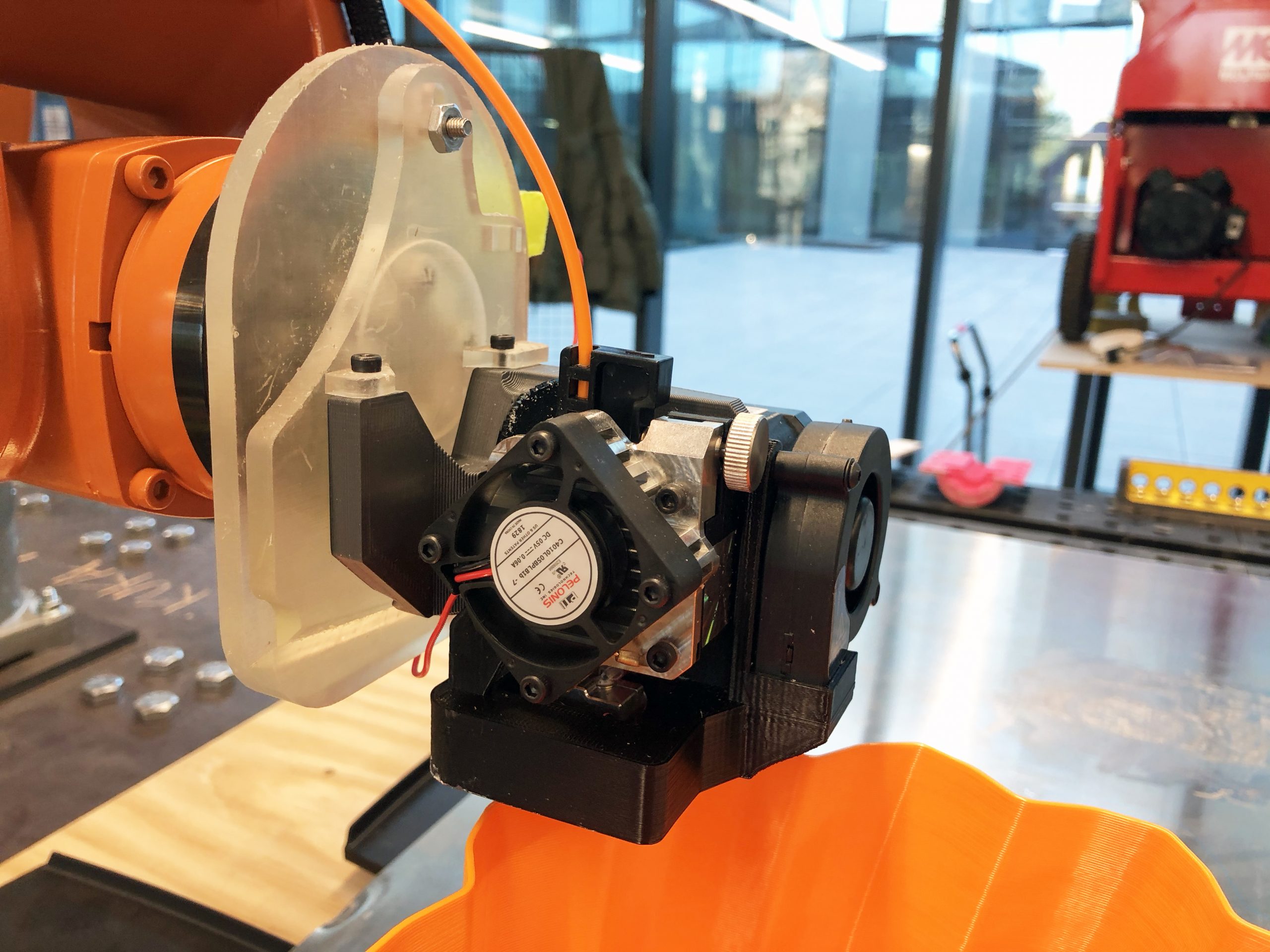

Hardware set up:

- 3D print attachment files

- Assemble toolhead electronics

- Mount toolhead with attachment to robotic arm

- Create tool in KUKA

- Set up the griddles with aluminum on top to create a flat surface

- Create base plane in KUKA

Software set up

- Note: This is set up so that the movement of the robotic arm and the control of the tool head are separate

- Flash firmware to the toolhead (you will need a USB cord)

- Load GCode onto an SD card and insert behind toolhead LCD screen – the GCode provided here is for ABS printing continuously without any retractionProduce geometry to 3D print

- Produce KR1100 tool path using KUKA PRC by Robots in Architecture

- Load onto KUKA the .SRC file produced from PRC

- Send .SRC to KUKA on AUT (Automatic)